Alpine gear usually fails quietly—zipper by zipper, seam by seam, under conditions where failure can’t be patched. For New Zealand’s alpine professionals, that failure isn’t theoretical. It happens on wet rock faces, in storms that last for days, and underloads that punish every stitch. Solving that kind of problem meant building something new. Inselberg worked with members of the Aoraki Mount Cook Alpine Rescue Team (AMCART) to build a shell that didn’t just survive conditions like these—but was made for them.

Among those involved from the start was Jamie Marr, a guide and former AMCART member with years of experience operating in high alpine terrain. Over a 36-month development process—driven by feedback, iteration, and field testing—he helped shape the concept into a working reality.

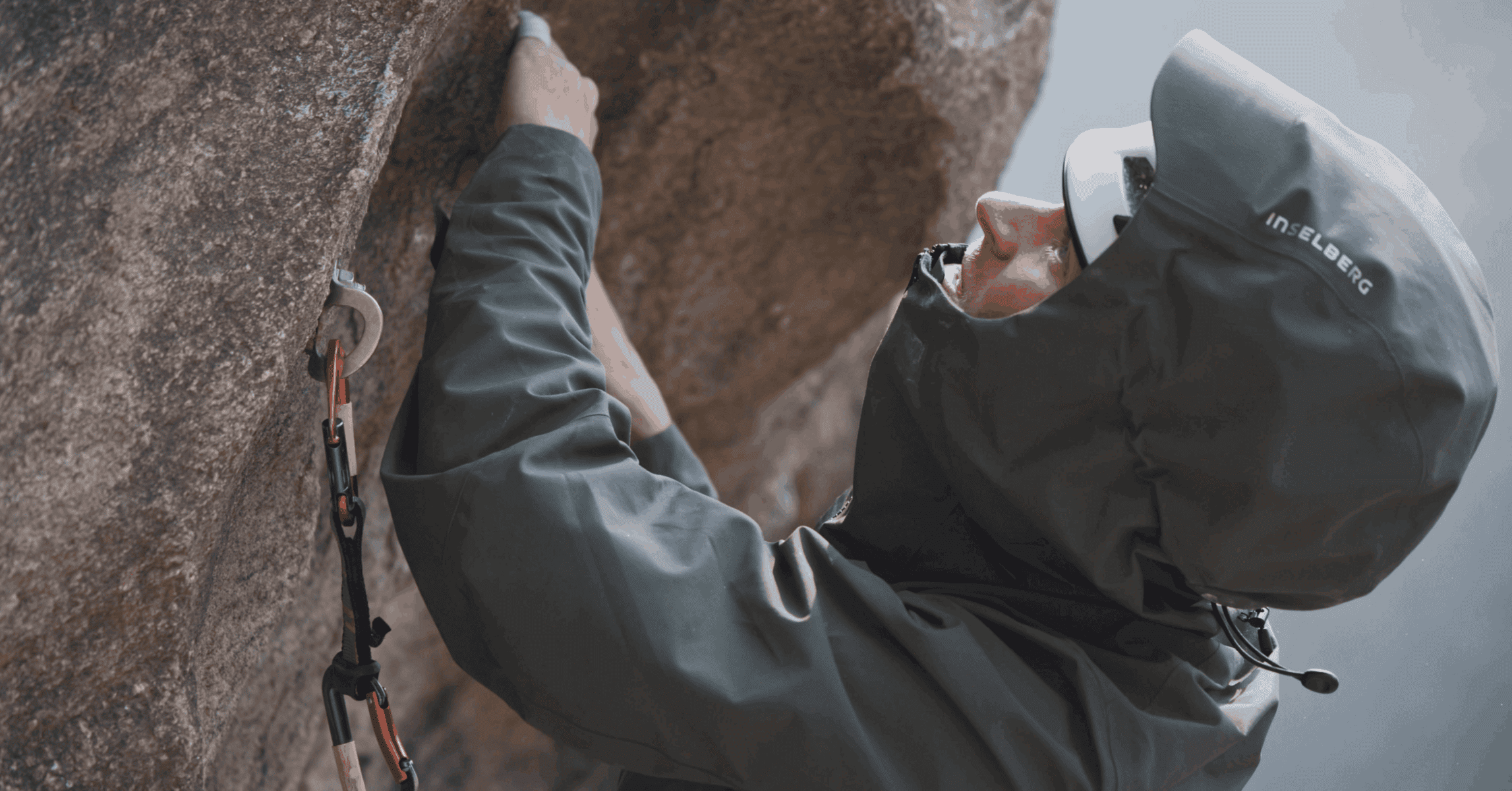

The solution was the Axiom Shell: a four-layer hardshell jacket engineered to operate at the margins—where rain turns to ice, where storms stall for days, and where gear must perform through constant friction, impact, and weather. When it came time for the final round of testing, Marr took a late-stage prototype to one of the harshest natural environments available: Baihe (White River), a granite gorge just north of Beijing.

Baihe is no pristine alpine basin. It is coarse, exposed, and relentless. Granite towers rise from the valley like forgotten ramparts of the Great Wall. The cliffs are riddled with razor-sharp cracks, slick slabs, and a sheer verticality rarely found so close to a city of twenty million. Katabatic winds funnel down the gullies and drop the temperature into the single digits.

“Granite is brutal,” said Marr. “It’s the kind of surface that destroys outerwear quickly. You feel every scrape. Over multiple days, I tested the jacket while climbing sharp cracks, hauling gear over abrasive surfaces, and scrambling through rough granite gullies. No failures. No breakdown. No tearing. That’s what I was there to prove.”

Marr’s feedback—documented daily—focused on abrasion resistance, freedom of movement, and overall fit during sustained climbs. Rather than relying on a pass/fail lab test, Inselberg treated this field trial as the final benchmark before release. When the jacket came back dusty and scraped but structurally sound, the team knew it had met the standard.

“Baihe was never about glamour testing,” said Jarlath Anderson, founder of Inselberg. “It was about real climbing, on exposed granite, in abrasive conditions, with unpredictable winds and significant temperature swings. Jamie didn’t wear this thing for a photo. He tried to break it. That’s what we needed.”

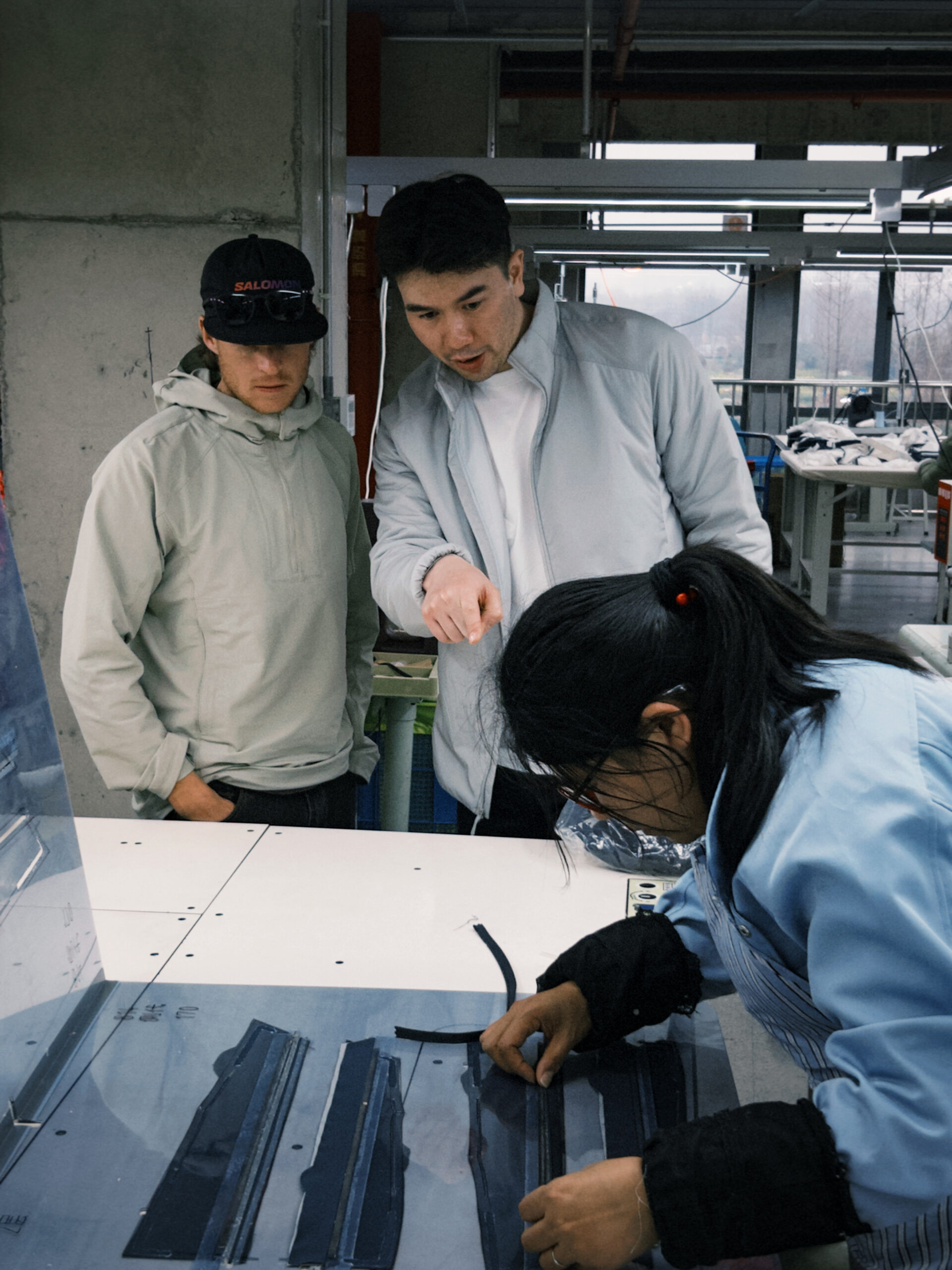

Anderson founded Inselberg in 2021 with a clear design philosophy: work backwards from real problems faced by alpine professionals. That meant no trend-driven roadmaps, no expanding seasonal colourways, and no rushing to market. Instead, each product begins with a use case—then gets prototyped, refined, and tested until it earns its place in a climber’s pack.

The Axiom Shell is the purest expression of that process. Eighteen full rounds of prototyping were completed over a three-year period. Early samples used asymmetrical seam patterns and different articulations between the left and right sides of the shell to enable real-time comparisons—a method Inselberg calls “Frankenstein prototyping.” Garments were returned to the brand’s development lab to be disassembled, analysed, and rebuilt, with pattern changes implemented within 48 hours.

From the start, Inselberg opted for a four-layer laminate construction—developed and produced in Japan—as the foundation of the shell. Rated to 40,000mm, it offers double the waterproof protection of most standard three-layer fabrics, while retaining breathability under sustained effort through zippered ventilation panels. It adds a margin of durability that matters when jackets are used for months at a time in ice, wind, and rain.

“Three-layer systems are great until they aren’t,” said Anderson. “When sideways rain and gusting wind hits you on an exposed ridgeline and you’ve still got hours to go, your shell has to hold. That’s why we chose a four-layer construction—it’s overbuilt by design.”

In keeping with Inselberg’s commitment to precision, the Axiom was built around a specific alpine use case. Every element was driven by need—no assumptions, no excess. This isn’t a jacket assembled from defaults. It’s the outcome of deliberate, technical decisions made through field testing, pattern refinement, and lab validation. No superfluous toggles. No decorative trims. Just engineered precision for serious alpine terrain.

Inselberg will mark the launch of the Axiom Shell with a five-day experiential space in Britomart, Auckland, from July 9–13. Designed to offer a hands-on look at the development process, the space will feature waterproof testing rigs, air-permeability demonstrations, and an abrasion testing station that mirrors the kind of punishment the Axiom endured on Baihe’s granite.

The goal is to make the technical story behind the product tangible, not just for climbers, but for anyone who wants to understand what it takes to build gear that performs when it matters most.

The Axiom Shell will be available for preorder on July 30th at inselberg.com.

About Inselberg

Founded in 2021, Inselberg is a New Zealand mountaineering brand committed to creating durable, purpose-driven products inspired by the rugged landscapes of New Zealand.

With a focus on precision, functionality, and longevity, Inselberg’s gear is designed to meet the highest standards of performance, ensuring that every piece is ready for the most demanding environments.

For more information visit inselberg.com